Micropipette puller

Manufacturing Multi-Barrel Micropipettes

Multi-barrel assemblies are mostly manufactured from borosilicate glass capillary tubes. The appropriate number of tubes is fused or glued together before being pulled. The two ends of this micropipette “blank” are then held by chucks of the puller, and a heating coil is used to gently soften the glass in the central portion. If a multi-barrel blank is made of individual glass capillaries, one of the chucks is rotated while the pipette blank is slowly pulled. This rotation and pulling cause the lengths of the glass tubes to fuse together. The combination of current supplied to the heating coil, and the degree and timing of the pull, may be varied to produce pipettes of different lengths and diameters. The open ends of the capillary tubes are splayed to facilitate access and prevent cross-contamination when filling.

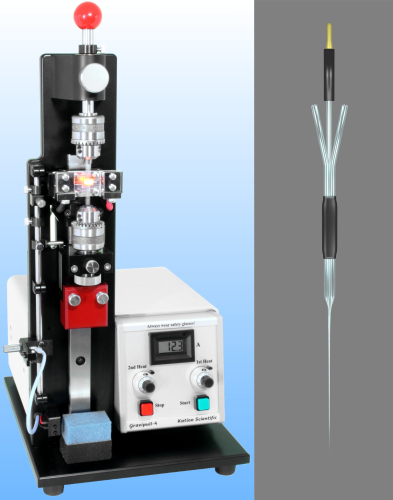

Gravipull-4 micropipette puller

The Gravipull-4 is designed for pulling multi-barrel glass micropipette assemblies or single-barrel glass micropipettes. It can effectively soften and pull glass capillary tubing constructions (blanks) with diameters of up to 0.25" (6.4 mm) and lengths of up to 6" (152 mm). The pull process is gravity-fed and utilizes a 6-stage weight system. The chuck, mounted on the lower sliding shaft, can be rotated and is pulled by the weights once the glass starts to soften. A bumper located at the bottom of the puller gently stops the lower glass holder, preventing damage to the lower piece of glass.

One notable feature of the Gravipull-4 is its ability to perform two-stage pulls, allowing the production of long- tapered micropipettes with sharp tips, reaching lengths of up to 4" (101 mm). The mechanical settings and weight system are highly adjustable, enabling the pulling of micropipettes in various sizes and shapes, both from multibarreled assemblies and individual glass tubes. The heating coil can be vertically positioned and repositioned during repetitive two-stage pulls. To ensure consistent pull sizes, adjustable shaft collars on the side bar enable vertical positioning of all essential movable parts, such as the heating coil, upper position of the sliding chuck, or the taper length setting mid-switch.

On the left side, you can see a sample two-stage pull of a three-barreled micropipette assembly. For a demonstration on how to use this puller, please watch the video available at this link: https://www.youtube.com/watch?v=QezaiN1yhag&t=4s

Specifications are as follows:

Blank dimension | 0.25" diameter x 6" length, maximum (6.4 mm x 152 mm) |

Slider’s travel | 4.4" (112 mm), vertical |

Taper length | 100 mm, maximum |

Pulling force | Gravity-fed, set by weights |

Weights | 0, 1, 2, and 3-unit masses |

Heater power | 12 VDC, maximum 20 A, controlled by pulse width modulation |

Heater wire | Kanthal AF, AWG 18 |

Display | Four-digit LCD showing heater currents in Amperes (A) |

Mains power input | Worldwide automatic, self-adjusting, ranging from 80 to 264 VAC, maximum 400W |

Mains frequency | 47Hzto63Hz |

Dimensions | 8.3" x 9.7" x 17.3" (Width x Depth x Height) or 21.0 cm x 24.5 cm x 44.0 cm |

Net weight | 16 lbs (7.3 kg) |

Shipping weight | 20 lbs (9.0 kg) |

The Gravipull-4 is covered by a one-year limited warranty and includes free technical email support. Additionally, customers in the US and the European Union are eligible for a 30-day money-back guarantee.